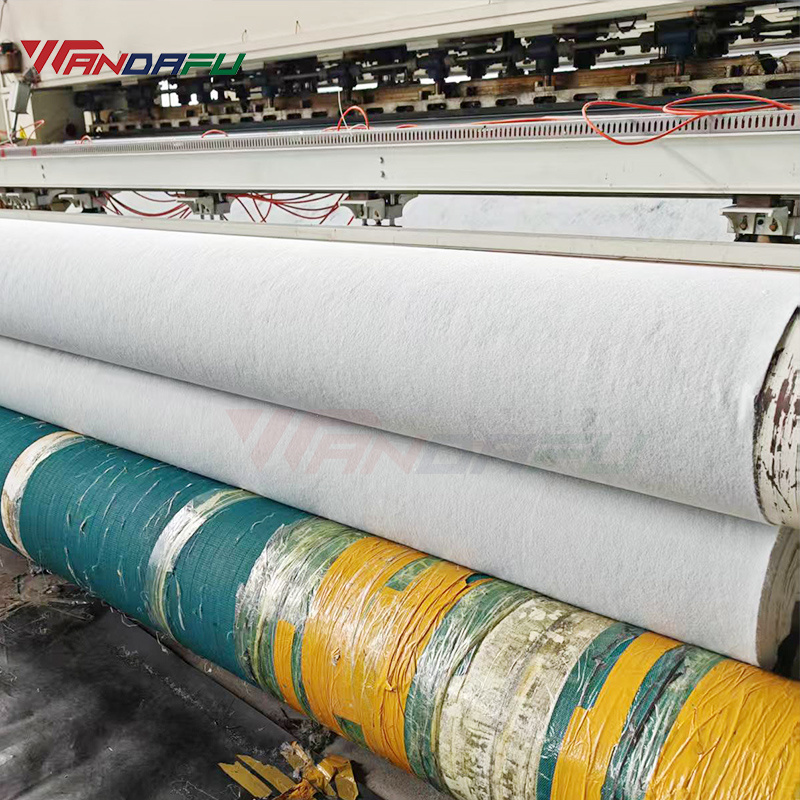

Staple Fiber Nonwoven Geotextile for Civil Engineering Projects

Release time:

2025-08-30

Staple Fiber Nonwoven Geotextile is a high-performance engineering material made from polypropylene or polyester staple fibers through processes including opening, carding, random web laying, and needle-punching. Designed to deliver exceptional permeability, filtration, and durability, this geotextile offers high tensile, tear, and puncture resistance, making it an ideal solution for a wide range of infrastructure applications.

Staple Fiber Nonwoven Geotextile is a high-performance engineering material made from polypropylene or polyester staple fibers through processes including opening, carding, random web laying, and needle-punching. Designed to deliver exceptional permeability, filtration, and durability, this geotextile offers high tensile, tear, and puncture resistance, making it an ideal solution for a wide range of infrastructure applications.

Product Features

-

High Strength

Maintains excellent strength and elongation both in dry and wet conditions thanks to its synthetic fiber composition. -

Corrosion Resistance

Resists degradation in soils and water with varying pH levels, ensuring long-term performance.

3 Superior Permeability

The porous structure between fibers ensures efficient water passage, reducing hydrostatic pressure and preventing soil washout.

-

Microbial Resistance

Immune to microorganisms and insect damage, providing lasting functionality in challenging environments. -

Easy Installation

Lightweight and flexible, it is easy to transport, lay, and construct, reducing labor and time costs.

Key Applications

Staple Fiber Nonwoven Geotextile is widely used in:

-

Water Conservancy & Hydraulic Engineering

-

Power & Mining Infrastructure

-

Highway & Railway Construction

-

Environmental Protection Projects

Specific Functions:

-

Separation: Prevents intermixing of different soil layers.

-

Drainage: Used in drainage systems for reservoirs, mines, and building foundations.

-

Erosion Control: Protects riverbanks, slopes, and coastal structures from scouring.

-

Reinforcement: Enhances subgrade stability for roads, runways, and railways.

-

Insulation: Provides antifreeze and thermal insulation in cold regions.

-

Crack Prevention: Used as a stress-relief layer in asphalt pavements.

Technical Specifications

-

Width: 1–6 m

-

Weight: 100–800 g/m²

-

Tensile Strength: ≥22.5 kN/m (as per project requirements)

-

Compliance: Meets JTJ/T239-2005 and other international standards

Installation Guidelines

Material Selection & Inspection

-

Only use geotextiles that have been tested and certified by accredited laboratories.

-

Avoid materials that show signs of aging or have been stored for extended periods.

Preparation & Sewing

-

Geotextile rolls are typically 2–3 m wide and can be sewn into larger sheets (e.g., 6 m width) using industrial sewing machines and nylon thread (strength ≥150 N).

-

Seam types: Butterfly or J-seam styles are recommended.

-

Store sewn geotextiles covered to prevent UV degradation before installation.

Base Preparation

-

The substrate (e.g., crushed stone layer) must be leveled to within 100 mm tolerance.

-

Remove sharp protrusions to avoid damaging the geotextile.

Equipment Used

-

5 kW generators

-

Portable sewing machines for on-site seaming

Why Choose Our Staple Fiber Nonwoven Geotextile?

-

All-in-one solution: separation, filtration, drainage, and protection.

-

Cost-effective with easy installation and reduced maintenance.

-

Customizable weight, width, and strength based on project needs.

-

Suitable for large-scale civil, environmental, and transportation projects.

This geotextile is an essential material in modern geotechnical and civil engineering, providing reliable performance and sustainability. For quotes or technical support, feel free to contact our team!

Latest News