Composite Geonet for Landfill Projects: A Successful Case Study in Indonesia

Release time:

2025-07-05

Composite Geonet is a high-performance geosynthetic material widely used in civil engineering and environmental projects for drainage, soil stabilization, and erosion control. By combining geotextiles and a geonet core, it provides superior filtration, strength, and fluid transmission compared to traditional methods. But what exactly is Composite Geonet made of, and how does it work? This article explores its composition, key benefits, and applications to help engineers and contractors make informed decisions.

Composite Geonet is a high-performance geosynthetic material widely used in civil engineering and environmental projects for drainage, soil stabilization, and erosion control. By combining geotextiles and a geonet core, it provides superior filtration, strength, and fluid transmission compared to traditional methods.

But what exactly is Composite Geonet made of, and how does it work? This article explores its composition, key benefits, and applications to help engineers and contractors make informed decisions.

What is Composite Geonet Made Of?

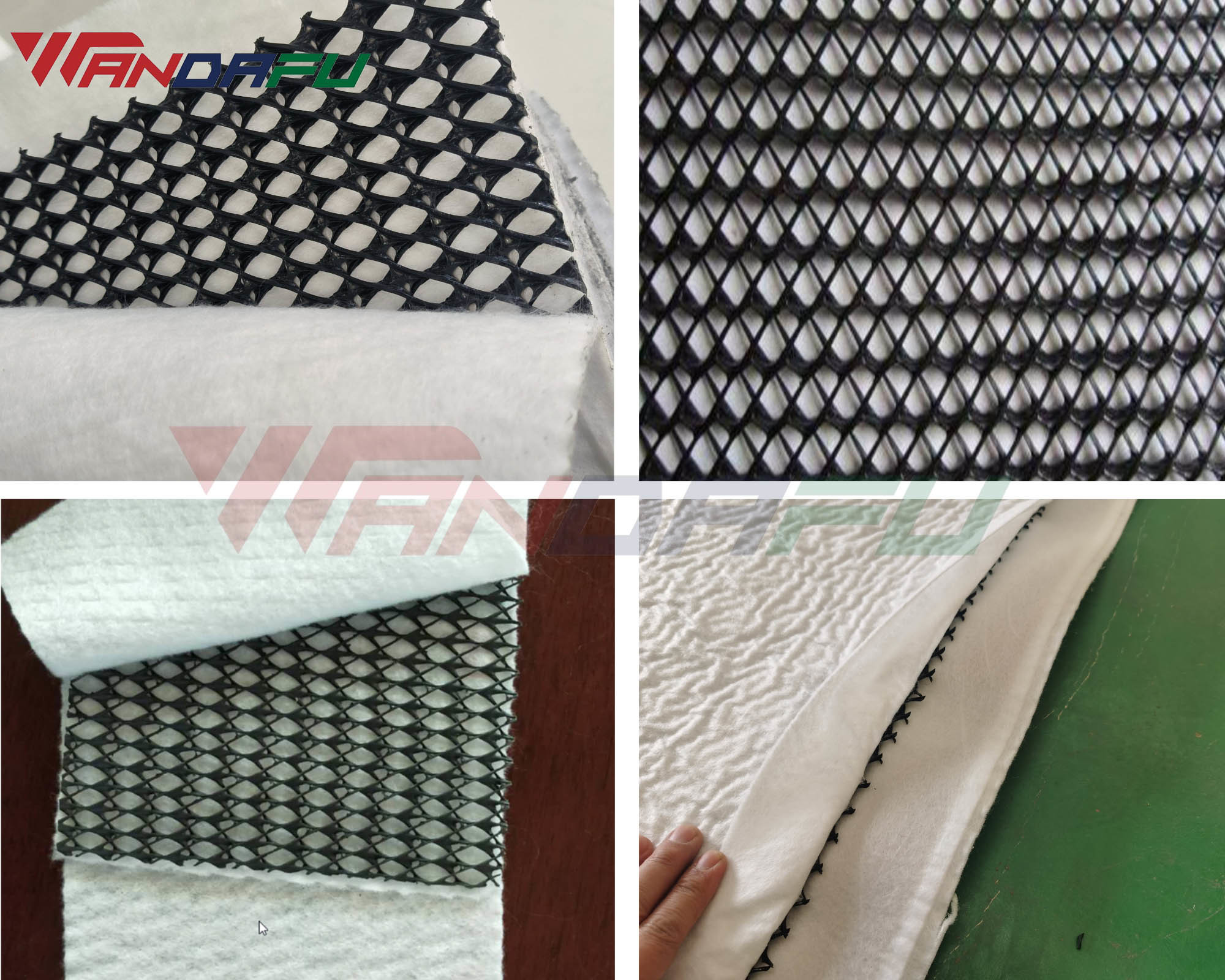

Composite Geonet consists of multiple layers, each serving a specific function:

1. Geonet Core (Drainage Layer)

-

Made from high-density polyethylene (HDPE) or polypropylene (PP).

-

Features a grid-like or ribbed structure for high in-plane flow capacity.

-

Provides rapid water/gas drainage while maintaining structural stability.

2. Geotextile Layers (Filtration & Protection)

Composite Geonet is typically sandwiched between geotextile layers, which can be:

-

Non-woven geotextiles (for filtration and separation).

-

Woven geotextiles (for added strength and reinforcement).

Functions of Geotextiles in Composite Geonet:

✔ Filtration – Prevents soil particles from clogging the geonet, ensuring long-term drainage efficiency.

✔ Separation – Keeps different soil layers from mixing, maintaining structural integrity.

✔ Protection – Shields the geonet from mechanical damage during installation.

✔ Reinforcement – Enhances load distribution and soil stability.

3. Bonding Method (Ensures Structural Integrity)

The layers are bonded using:

-

Thermal bonding (heat-sealing for durability).

-

Needle-punching (mechanical interlocking for strength).

-

Adhesive bonding (chemical bonding for flexibility).

Why Choose Composite Geonet? Key Benefits

✅ Superior Drainage Performance

-

3x faster drainage than gravel systems, preventing waterlogging.

-

Reduces hydrostatic pressure in retaining walls and foundations.

✅ Enhanced Soil Stabilization

-

Distributes loads evenly, preventing soil settlement.

-

Ideal for road bases, embankments, and slopes.

✅ Effective Erosion Control

-

Protects riverbanks, shorelines, and landfills from soil displacement.

✅ Cost & Time Savings

-

Lightweight & easy to install – Reduces labor and transportation costs.

-

Long-lasting – Resists UV rays, chemicals, and biological degradation.

✅ Eco-Friendly Solution

-

Recyclable materials – Reduces environmental impact.

-

Reduces need for natural aggregates (e.g., gravel).

Recently, one of our Indonesian clients secured a major landfill tender and chose our high-quality 800g/m² Composite Geonet for their project.

This case study explores:

✔ Project requirements & our solution

✔ Technical specifications of the Composite Geonet supplied

✔ Why our product was selected over competitors

✔ Future supply opportunities

Project Overview: Landfill Liner & Drainage System

Our client, a leading civil engineering firm in Indonesia, won a landfill construction tender requiring:

-

30,000 m² of Composite Geonet

-

Function:

-

Geotechnical protective liner (preventing soil contamination)

-

Efficient drainage layer (managing leachate and groundwater)

-

Our Recommended Solution: 800g/m² Composite Geonet

After evaluating their needs, we proposed our high-performance Composite Geonet with the following specifications:

| Component | Specification |

|---|---|

| Total Weight | 800 g/m² |

| Geotextile Layer | 300 g/m² (non-woven, thermally bonded) |

| Dual-Rib Geonet Core | 500 g/m² (HDPE, high drainage capacity) |

| Bonding Method | Heat-bonded on one side for secure adhesion |

Key Advantages of Our Composite Geonet

✅ Superior Drainage – The dual-rib geonet core ensures fast leachate flow, preventing liquid buildup.

✅ Robust Protection – The 300g/m² geotextile acts as a filter and separator, preventing soil clogging.

✅ Durable & Long-Lasting – Resists chemical corrosion and mechanical stress in landfill environments.

Testing & Approval Process

Before bulk production, we provided sample rolls to the client’s engineering team for laboratory testing. The results confirmed:

✔ Excellent hydraulic conductivity (meeting ASTM D4716 standards)

✔ High tensile strength (resisting installation stresses)

✔ Effective filtration (preventing soil particle migration)

After approval, we delivered 30,000 m² of Composite Geonet on schedule.

Successful Implementation & Client Feedback

Our Composite Geonet performed flawlessly in their landfill project by:

✔ Preventing leachate accumulation (critical for environmental safety)

✔ Protecting the geomembrane liner from punctures and soil pressure

✔ Reducing long-term maintenance costs

The client was highly satisfied and confirmed:

"The Composite Geonet provided optimal drainage and liner protection. We will continue sourcing from your company for future phases."

Future Supply Opportunities

Due to the successful collaboration, the client has indicated additional demand in the coming months for:

-

Expansion of the landfill site

-

New waste containment projects

We are prepared to supply more Composite Geonet and offer:

✔ Competitive pricing for bulk orders

✔ Custom specifications (different weights, geotextile types)

✔ Fast logistics support across Southeast Asia

Why Choose Our Composite Geonet for Landfills?

| Feature | Our Product | Competitors |

|---|---|---|

| Drainage Efficiency | ✅ High-flow dual-rib geonet | ❌ Single-layer designs |

| Filtration | ✅ 300g/m² non-woven geotextile | ❌ Lighter, less durable |

| Durability | ✅ UV & chemical resistant | ❌ Degrades faster |

| Customization | ✅ Adjustable weight & bonding | ❌ Limited options |

Conclusion

This Indonesian landfill project demonstrates how our 800g/m² Composite Geonet delivers reliable drainage and liner protection in demanding environments. With proven performance and client trust, we are ready to support more large-scale geosynthetic needs.

Need Composite Geonet for Your Project?

📞 Contact us today for a free consultation & quote!

Latest News