How to Install Needle-Punched Nonwoven Geotextile Fabric: A Step-by-Step Guide

Release time:

2025-04-25

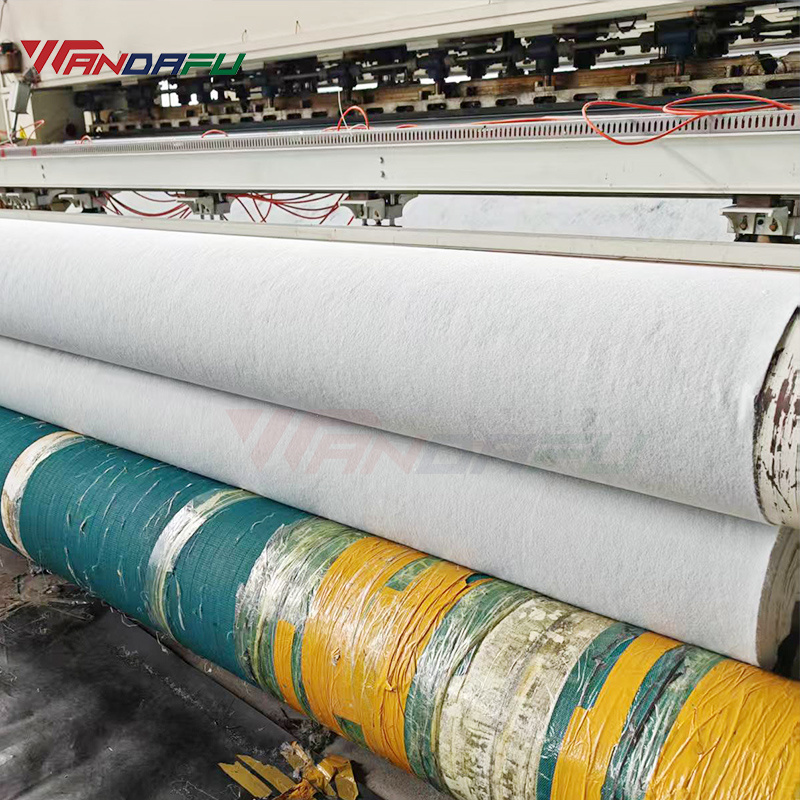

Needle-punched nonwoven geotextile fabric is a versatile material used in construction, landscaping, and civil engineering projects for filtration, separation, and reinforcement. Proper installation ensures maximum performance and longevity. This guide covers best practices for installing needle-punched geotextile fabric, including storage, handling, laying, and repair methods to meet industry standards.

Needle-punched nonwoven geotextile fabric is a versatile material used in construction, landscaping, and civil engineering projects for filtration, separation, and reinforcement. Proper installation ensures maximum performance and longevity. This guide covers best practices for installing needle-punched geotextile fabric, including storage, handling, laying, and repair methods to meet industry standards.

1. Storage, Handling, and Transportation

Storage Requirements

-

Store rolls on a flat, dry surface to prevent water damage.

-

Stack no more than four rolls high to avoid deformation.

-

Cover with UV-resistant material to prevent sunlight degradation.

-

Keep identification tags and documentation intact for quality tracking.

Transportation & Handling

-

Handle rolls carefully to avoid edge damage or tears.

-

Use forklifts or lifting straps to prevent roll deformation.

-

Damaged rolls must be repaired before use; severely damaged rolls should be discarded.

-

Avoid contact with chemicals or oils that could degrade the fabric.

2. Geotextile Installation Methods

A. Manual Unrolling & Placement

-

Unroll the fabric smoothly, avoiding wrinkles or folds.

-

Allow extra material (5-10%) for ground movement and adjustments.

-

Overlap adjacent rolls by 300–900 mm (12–36 inches) for proper seam strength.

B. Seaming Techniques

Needle-punched geotextile can be joined using:

-

Overlap Seaming (No Sewing)

-

Minimum 300 mm (12 inches) overlap for standard applications.

-

Secure with landscape staples or sandbags to prevent shifting.

-

-

Sewn Seams (For High-Stress Areas)

-

Use continuous stitching (not spot stitching).

-

Stitch type: Double-lock chain stitch for durability.

-

Needle distance from edge: ≥25 mm (1 inch).

-

Thread must be UV-resistant and chemical-proof.

-

-

Thermal Bonding (Heat Welding)

-

Best for permanent installations (e.g., landfills).

-

Use a hot air welder with controlled temperature settings.

-

3. Key Installation Requirements

A. Subgrade Preparation

-

Remove sharp rocks, roots, and debris to prevent punctures.

-

Compact and level the soil to avoid uneven stress on the fabric.

B. Anchoring & Securing

-

Anchor one end (e.g., at the top of a slope) before unrolling.

-

Use sandbags, staples, or adhesive to hold the fabric in place.

C. Edge & Overlap Fixing

-

Overlap seams parallel to slope direction (avoid cross-slope seams).

-

For slopes, no horizontal seams except for repairs.

D. Protection Before Backfilling

-

Cover with sand or gravel immediately to prevent UV exposure.

-

Avoid heavy machinery directly on the fabric.

4. Inspection & Repair Procedures

A. Daily Visual Checks

-

Inspect for tears, punctures, or seam failures.

-

Mark defects with waterproof tape for later repair.

B. Repair Methods

-

Small Holes (<50 mm)

-

Patch with same-material geotextile, extending 200 mm (8 inches) beyond the damage.

-

Secure with heat welding or adhesive.

-

-

Large Tears (>10% of roll width)

-

Cut out the damaged section and re-stitch or weld the remaining fabric.

-

-

Seam Failures

-

Re-stitch with stronger thread or reinforce with an additional overlap.

-

5. Common Mistakes to Avoid

❌ Insufficient Overlap → Leads to separation under load.

❌ Poor Subgrade Prep → Causes punctures and premature failure.

❌ Exposed to UV for Too Long → Weakens fabric before backfilling.

❌ Using Damaged Rolls → Reduces effectiveness and lifespan.

Conclusion

Proper installation of needle-punched nonwoven geotextile fabric ensures optimal filtration, separation, and reinforcement in construction projects. Follow these steps for long-lasting performance:

✔ Store & handle carefully to avoid damage.

✔ Prepare the subgrade properly before laying.

✔ Use correct seaming techniques (overlap, sewing, or welding).

✔ Inspect and repair defects before backfilling.

By following these guidelines, your geotextile installation will meet engineering standards and maximize durability.

Latest News