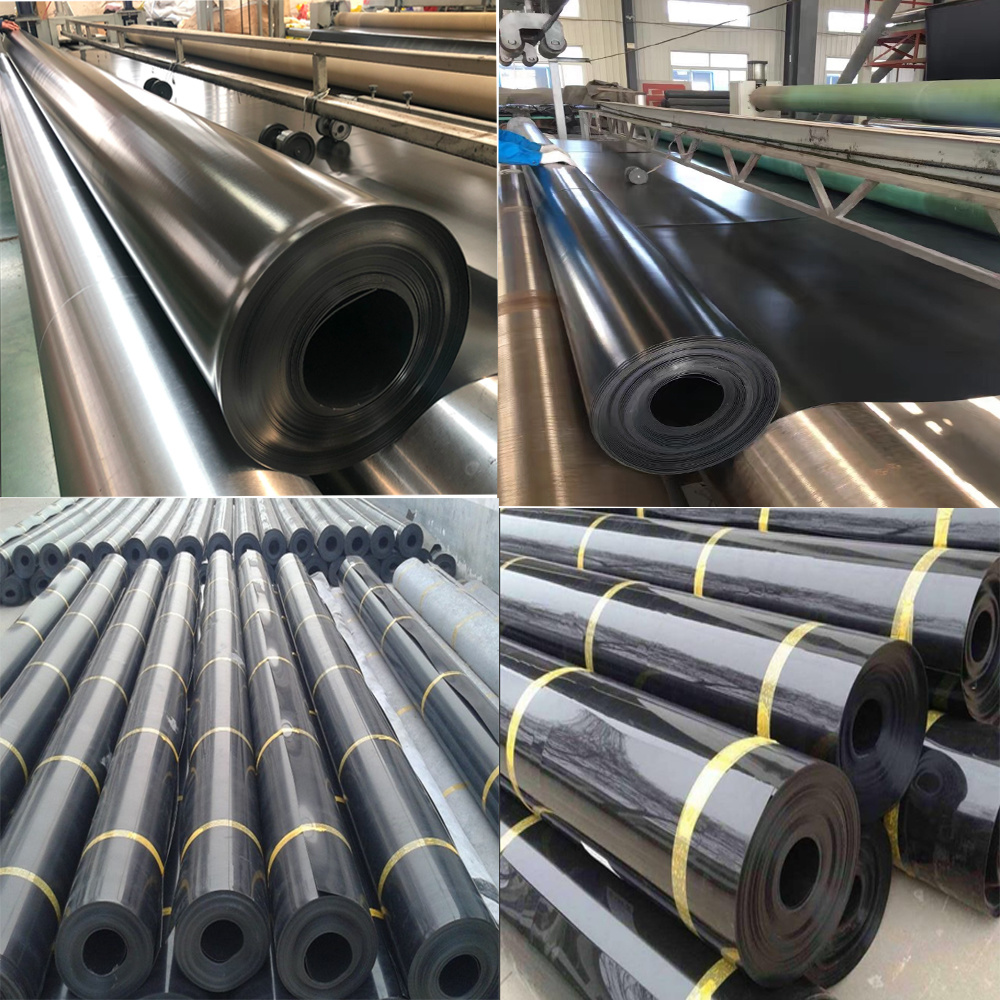

ASTM Standard UV Resistance Landfill HDPE Geomembrane (1mm)

Subclassification:

Geomembrane

Key words:

Geomembrane

Email:

WhatsApp:

Product Details

| Name; geomembrane |

| Length; 1-6m |

| Thickness; 0.3 -2 mm |

| Material; HDPE, LDPE, PVC, LLDPE |

| Color; Black, white, blue, customized products can be supported according to customer needs |

HDPE materials practically do not change their properties inside temperature go from -60 degrees C to +60 degrees C. They are resistant to the most chemical substances : acid, salts, alkaline, fats and for example. HDPE membranes are not spoilt by fungus, microbes, are resistant against plant root growing and ultraviolet radiation and do not affect the standard of drinkable water.

Slope stability and waste stability are important considerations within the basal lining to any landfill cell. The smooth HDPE linings are well suited to the relatively flat conditions of the base but where steeper side slopes (batters) are required, it is often desirable to choose a liner with a textured surface which can help to resist any sliding movements between the liner surface and the waste body itself.

-

Resist aging performance: HDPE film has high quality of resist aging, ultraviolet and decompose, can be used in the air. The life-span of material Can reach 50-70 years providing guarantee for environmental anti-seepage.

-

Resist plant root: HDPE film has good anti-puncture ability, can against almost plant foots.

-

High machine strength: HDPE film has excellent flexibility and distortion, can adapt un-even sedimentation. Extend strength is 28MP, elongation at break is 700%.

-

Good benefit: new technology improved HDPE film's anti-seepage, low the cost compare with the additional material .via practical testing, HDPE Geomembrane can save 50% project cost

-

Fast construction: HDPE film has high flexibility, multi-specification and pave forms, can cater for different engineering demand.

|

|

|

|

|

|

Properties |

Test Method |

GMSH050 |

GMSH075 |

GMSH100 |

GMSH150 |

GMSH200 |

|

■ Thickness |

ASTM D5199 |

0.50 mm |

0.75 mm |

1.00 mm |

1.50 mm |

2.00 mm |

|

■ Density |

ASTM D1505 |

0.940 g/cc |

0.940 g/cc |

0.940 g/cc |

0.940 g/cc |

0.940 g/cc |

|

Tensile Properties |

|

|

|

|

|

|

|

■ Yield strength ■ Break strength ■ Yield elongation ■ Break elongation |

ASTM D6693 Type IV

|

7 kN/m 13 kN/m 12% 700% |

11 kN/m 20 kN/m 12% 700% |

15 kN/m 27 kN/m 12% 700% |

22 kN/m 40 kN/m 12% 700% |

29 kN/m 53 kN/m 12% 700% |

|

■ Tear Resistance |

ASTM D1004 |

62 N |

93 N |

125 N |

187 N |

249 N |

|

■ Puncture Resistance |

ASTM D4833 |

160 N |

240 N |

320 N |

480 N |

640 N |

|

■ Stress Crack Resistance |

ASTM D5397 |

500 hrs |

500 hrs |

500 hrs |

500 hrs |

500 hrs |

|

■ Carbon Black Content |

ASTM D1603 |

2.0% |

2.0% |

2.0% |

2.0% |

2.0% |

|

■ Carbon Black Dispersion |

ASTM D5596 |

For 10 different views:9 in Categories 1 or 2 and 1 in Category 3 |

||||

|

■ Oxidative Induction Time (OIT) |

ASTM D3895 |

100 min. |

100 min. |

100 min. |

100 min. |

100 min. |

|

■ UV Resistance High Pressure OIT retained after 1600hrs |

ASTM D5885 |

50% |

50% |

50% |

50% |

50% |

|

Dimensions |

|

|

|

|

|

|

|

■ Roll Width (m) |

|

7 |

7 |

7 |

7 |

7 |

|

■ Roll Length (m) |

|

420 |

280 |

210 |

140 |

105 |

|

|

Honor

MESSAGE