Playground Pp Biaxial Geogrid Bx1100 Factory Price Polypropylen Biaxial Geogrid for Road Civil Engineering

Subclassification:

PP Biaxial Geogrid

Key words:

PP Biaxial Geogrid

Email:

WhatsApp:

Product Details

| PP Biaxial Geogrid |

| Material; polypropylene |

| Tension; 15-55KN(support customization) |

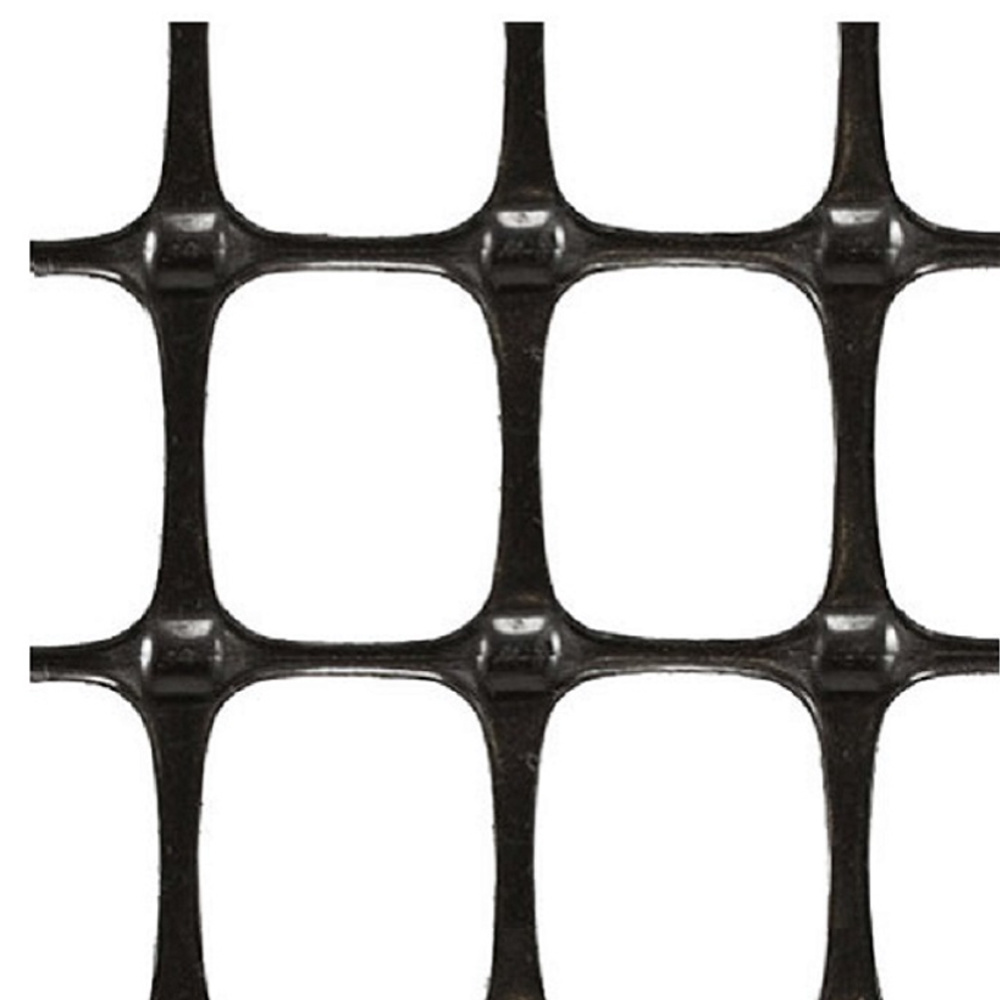

Biaxial geogrids are referred to as biaxial geogrids due to the fact they comprise comparable electricity in each the laptop and go laptop direction. It does now not always imply they have the identical electricity in each instructions simply that the geogrids are designed to supply guide in each directions. Biaxial geogrids can be knitted, woven or extruded however the majority are extruded. Extruded biaxial geogrids are typically extruded the usage of polypropylene with a small quantity of carbon black delivered to supply the geogrid the capacity to face up to UV degradation. Biaxial geogrid's main software is for use in base stabilization. By setting the geogrid in the gravel base so that it can interlock with gravel above and beneath you can lengthen the provider lifestyles or decrease the complete quantity of combination wanted for a road or parking lot application.

1. Increase the bearing capability of the roadbed and basis and lengthen their carrier life.

2. Prevent street floor and basis from sinking or flawing, preserve easy and lovely floor surface.

3. Convenient development saves time and labor, minimize mounting time and limit protection expense.

4. Prevent culverts from flawing.

5. Enhance earth slope and stop water loss and soil erosion.

6. Decrease under layer thickness and keep manufacturing cost.

7. Enhance the steadiness of facet slope turf internet patch to enhance greening.

8. Replace wire netting used in mine as intermediate ceiling netting.

|  |  |  |  |

Item |

Test Method | Unit | PBX1515 | PBX2020 | PBX3030 | PBX4040 | PBX5050 | |||||

MD | TD | MD | TD | MD | TD | MD | TD | MD | TD | |||

Polymer | - | - | PP | |||||||||

Minimum Carbon Black | ASTM D 4218 | % | 2 | |||||||||

Tensile Strength | ASTM D 6637 | kN/m | 15 | 15 | 20 | 20 | 30 | 30 | 40 | 40 | 50 | 50 |

Tensile Strength @ 2% Strain | ASTM D 6637 | kN/m | 5 | 5 | 7 | 7 | 10.5 | 10.5 | 14 | 14 | 17.5 | 17.5 |

Tensile Strength @ 5% Strain | ASTM D 6637 | kN/m | 10.5 | 10.5 | 14 | 14 | 21 | 21 | 28 | 28 | 35 | 35 |

Elongation | ASTM D 6637 | % | 13 | 13 | 13 | 13 | 13 | 13 | 13 | 13 | 13 | 13 |

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 | 93 | 93 | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 7748 | mg-cm | 250,000 | 750,000 | 2,000,000 | 4,800,000 | 8,000,000 | |||||

Aperture Stability | ASTM D 7864 | m-N/deg | 0.32 | 0.50 | 0.75 | 0.98 | 1.10 | |||||

Aperture Size | - | mm | 38 | 38 | 38 | 38 | 36 | 36 | 35 | 35 | 33 | 33 |

Roll Width | - | m | 3.95 or 5.95 | |||||||||

Roll Length | - | m |

| |||||||||

Notes MD = Machine Direction; TD = Transverse Direction

Honor

MESSAGE