30 Mil Impermeable Liner HDPE EPDM Pond Liner Geomembrane

Subclassification:

Geomembrane

Key words:

Geomembrane

Email:

WhatsApp:

Product Details

| Name; geomembrane |

| Length; 1-6m |

| Thickness; 0.3 -2 mm |

| Material; HDPE, LDPE, PVC, LLDPE |

| Color; Black, white, blue, customized products can be supported according to customer needs |

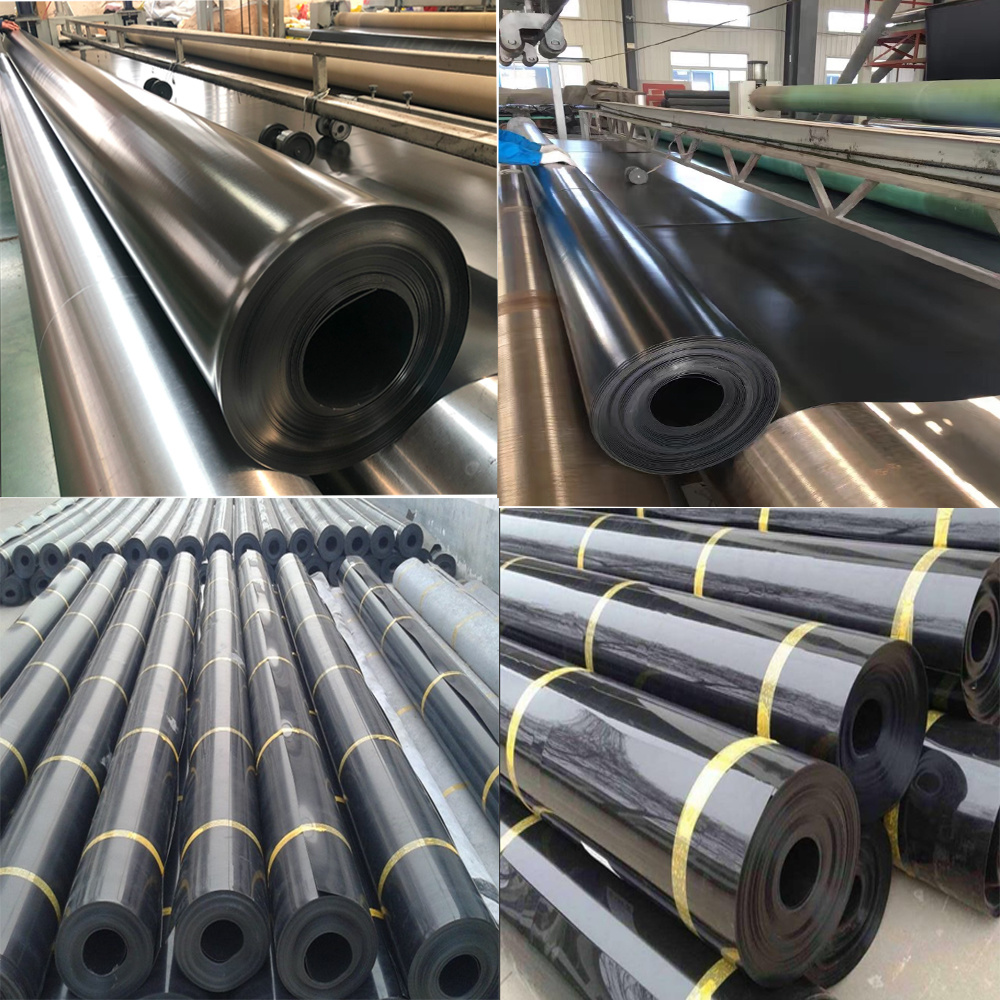

Our excessive density polyethylene (HDPE) geomembranes supply an impermeable barrier towards a broad vary of solids and liquids. They showcase first-rate chemical and UV resistance,impermeability, and excessive yield and welded seam strengths, which is extensively used as the liner.(model in accordance to the thickness of distinction, extraordinary thickness and exceptional price) manufacturing capacity: thickness:0.1 mm -6 mm, width: 1-8 meters. It is appropriate for seepage manipulate in one-of-a-kind industries, and is broadly used for aquaculture, seepage control, reservoirs or sewage remedy ponds.

1:Suitable for lining of landfills, river embankments, tailings dams, sewage dams and reservoirs, channels and other hydraulic ponds.

2:Anti-seepage & lining for subway, basement and tunnel.

3:Saline seepage and water proofing for roadbed and other foundation.

4:Used for seepage-proofing lining of embankment and dam, vertical impermeable layer for foundation, construction of cofferdams, fertilizer plants.

5:Used in sea water & freshwater aquaculture ponds.

|

|

|

|

|

|

Properties |

Test Method |

GMSH050 |

GMSH075 |

GMSH100 |

GMSH150 |

GMSH200 |

|

■ Thickness |

ASTM D5199 |

0.50 mm |

0.75 mm |

1.00 mm |

1.50 mm |

2.00 mm |

|

■ Density |

ASTM D1505 |

0.940 g/cc |

0.940 g/cc |

0.940 g/cc |

0.940 g/cc |

0.940 g/cc |

|

Tensile Properties |

|

|

|

|

|

|

|

■ Yield strength ■ Break strength ■ Yield elongation ■ Break elongation |

ASTM D6693 Type IV

|

7 kN/m 13 kN/m 12% 700% |

11 kN/m 20 kN/m 12% 700% |

15 kN/m 27 kN/m 12% 700% |

22 kN/m 40 kN/m 12% 700% |

29 kN/m 53 kN/m 12% 700% |

|

■ Tear Resistance |

ASTM D1004 |

62 N |

93 N |

125 N |

187 N |

249 N |

|

■ Puncture Resistance |

ASTM D4833 |

160 N |

240 N |

320 N |

480 N |

640 N |

|

■ Stress Crack Resistance |

ASTM D5397 |

500 hrs |

500 hrs |

500 hrs |

500 hrs |

500 hrs |

|

■ Carbon Black Content |

ASTM D1603 |

2.0% |

2.0% |

2.0% |

2.0% |

2.0% |

|

■ Carbon Black Dispersion |

ASTM D5596 |

For 10 different views:9 in Categories 1 or 2 and 1 in Category 3 |

||||

|

■ Oxidative Induction Time (OIT) |

ASTM D3895 |

100 min. |

100 min. |

100 min. |

100 min. |

100 min. |

|

■ UV Resistance High Pressure OIT retained after 1600hrs |

ASTM D5885 |

50% |

50% |

50% |

50% |

50% |

|

Dimensions |

|

|

|

|

|

|

|

■ Roll Width (m) |

|

7 |

7 |

7 |

7 |

7 |

|

■ Roll Length (m) |

|

420 |

280 |

210 |

140 |

105 |

|

|

Honor

MESSAGE