Customer-Made Textured Geomembrane for Building Construction

Subclassification:

Geomembrane

Key words:

Geomembrane

Email:

WhatsApp:

Product Details

| Name; geomembrane |

| Length; 1-6m |

| Thickness; 0.3 -2 mm |

| Material; HDPE, LDPE, PVC, LLDPE |

| Color; Black, white, blue, customized products can be supported according to customer needs |

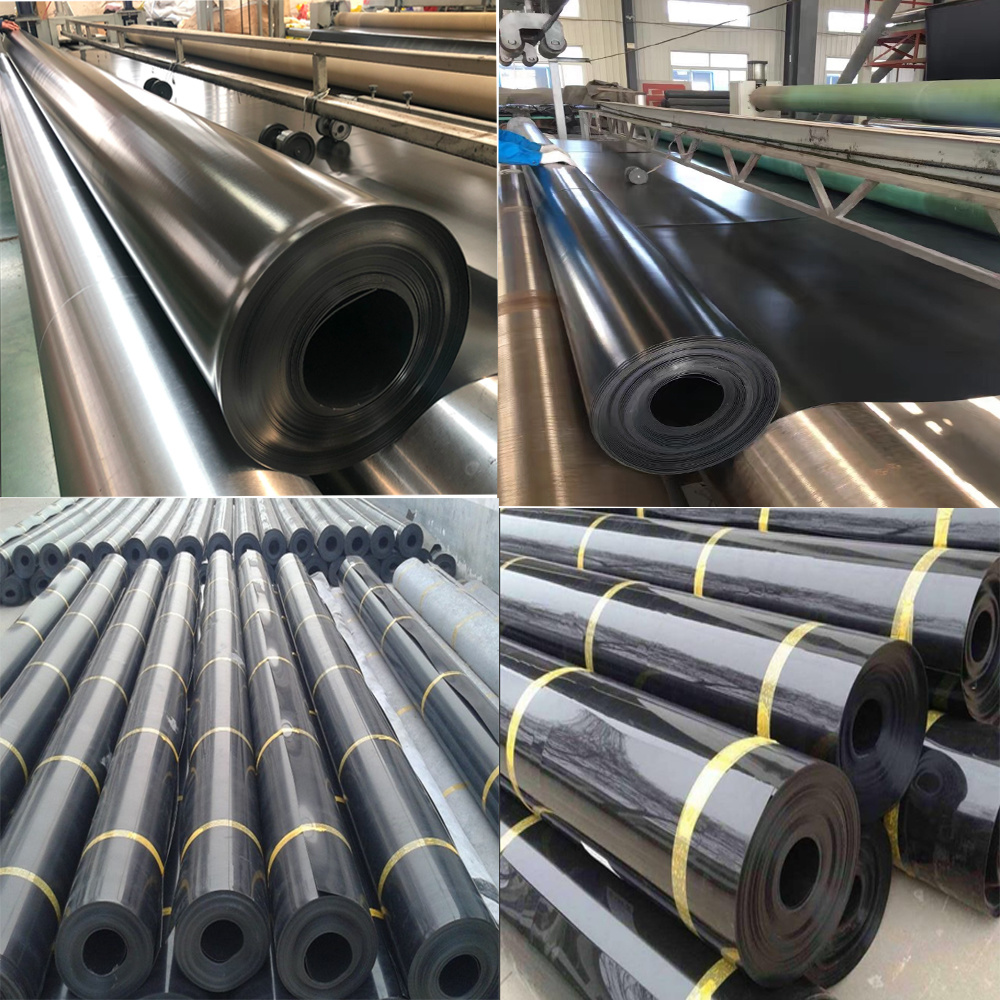

HDPE Geomembrane is a impermeable polymer liner and the biggest kind of geosynthetics.

HDPE Smooth Geomembrane carries about 97.5% polyethylene, 2.2% carbon black and hint quantities of antioxidants and warmness stabilisers. It has amazing chemical resistance, mechanical properties, environmental stress crack resistance, dimensional balance and thermal getting older characteristics.

HDPE textured geomembrane is dealt with with spray roughening method on the floor of easy geomembrane, which can radically expand the engineering adaptability of geomembrane. Its mechanical homes are constant with the HDPE clean geomembrane and in the meantime it is of an high-quality direct shear friction coefficient.

|

|

|

|

|

- High anti-seepage coefficient (1×10-17cm/s)

- High tensile strength. High tear resistance

- Good flexibility and elasticity, adapt to uneven geological settlement

- Resistant to sturdy acid, alkali, and oil corrosion, with splendid chemical corrosion resistance

- Good warmth resistance and bloodless resistance. With extensive applicability to climatic conditions

- Resistance to ultraviolet radiation. Good anti-aging performance

- Environmental protection, tremendous virgin plastic and carbon black particles do no longer comprise any preservatives and do now not pollute water and soil

- Easy to weld, convenient to installation and construct.

- Cost-effective

|

|

|

|

|

|

Properties |

Test Method |

GMSH050 |

GMSH075 |

GMSH100 |

GMSH150 |

GMSH200 |

|

■ Thickness |

ASTM D5199 |

0.50 mm |

0.75 mm |

1.00 mm |

1.50 mm |

2.00 mm |

|

■ Density |

ASTM D1505 |

0.940 g/cc |

0.940 g/cc |

0.940 g/cc |

0.940 g/cc |

0.940 g/cc |

|

Tensile Properties |

|

|

|

|

|

|

|

■ Yield strength ■ Break strength ■ Yield elongation ■ Break elongation |

ASTM D6693 Type IV

|

7 kN/m 13 kN/m 12% 700% |

11 kN/m 20 kN/m 12% 700% |

15 kN/m 27 kN/m 12% 700% |

22 kN/m 40 kN/m 12% 700% |

29 kN/m 53 kN/m 12% 700% |

|

■ Tear Resistance |

ASTM D1004 |

62 N |

93 N |

125 N |

187 N |

249 N |

|

■ Puncture Resistance |

ASTM D4833 |

160 N |

240 N |

320 N |

480 N |

640 N |

|

■ Stress Crack Resistance |

ASTM D5397 |

500 hrs |

500 hrs |

500 hrs |

500 hrs |

500 hrs |

|

■ Carbon Black Content |

ASTM D1603 |

2.0% |

2.0% |

2.0% |

2.0% |

2.0% |

|

■ Carbon Black Dispersion |

ASTM D5596 |

For 10 different views:9 in Categories 1 or 2 and 1 in Category 3 |

||||

|

■ Oxidative Induction Time (OIT) |

ASTM D3895 |

100 min. |

100 min. |

100 min. |

100 min. |

100 min. |

|

■ UV Resistance High Pressure OIT retained after 1600hrs |

ASTM D5885 |

50% |

50% |

50% |

50% |

50% |

|

Dimensions |

|

|

|

|

|

|

|

■ Roll Width (m) |

|

7 |

7 |

7 |

7 |

7 |

|

■ Roll Length (m) |

|

420 |

280 |

210 |

140 |

105 |

|

|

|

|

Honor

MESSAGE