HDPE Geomembrane EPDM Pond Liner Smooth Surface Geomembrane

Subclassification:

Geomembrane

Key words:

Geomembrane

Email:

WhatsApp:

Product Details

| Name; geomembrane |

| Length; 1-6m |

| Thickness; 0.3 -2 mm |

| Material; HDPE, LDPE, PVC, LLDPE |

| Color; Black, white, blue, customized products can be supported according to customer needs |

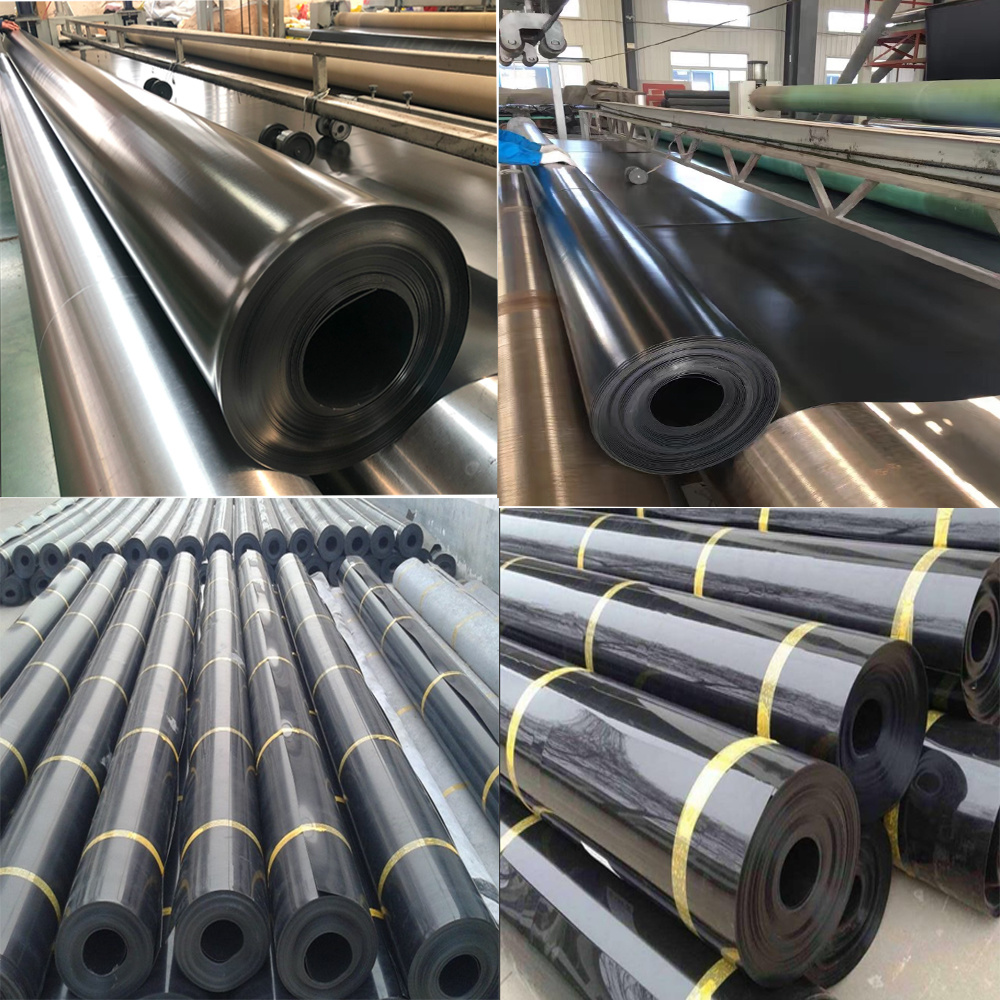

The manufacturing manner of geomembrane typically consists of the following steps:

Raw cloth preparation: Select splendid polymer materials, such as polyethylene (HDPE), polypropylene (PP), etc., to put together and combine the uncooked materials.

Processing mixing: feeding uncooked substances into an extruder or injection molding computer for processing and mixing, making them in a fluid state.

Extrusion molding: The processed combination is exceeded thru an extruder and molded into a sheet or roll structure of a geotextile film.

|

|

|

|

|

Cutting and processing: According to extraordinary specs and requirements, reduce and method the extruded geomembrane to meet the wants of customers.

Quality inspection: Conduct excellent inspection on the produced geomembrane, such as overall performance assessments such as tensile strength, put on resistance, and chemical corrosion resistance.

Packaging and delivery: After strict first-class inspection, the geosynthetic movie is packaged and offered to clients or suppliers earlier than leaving the factory.

|

|

|

|

|

This is the widely wide-spread manufacturing system for geomembranes, and the particular manufacturing procedure may additionally range relying on the necessities of one-of-a-kind producers and products. I hope the above facts can be beneficial to you. If you have any different questions or want in addition information, please sense free to let me know.

|

Properties |

Test Method |

GMSH050 |

GMSH075 |

GMSH100 |

GMSH150 |

GMSH200 |

|

■ Thickness |

ASTM D5199 |

0.50 mm |

0.75 mm |

1.00 mm |

1.50 mm |

2.00 mm |

|

■ Density |

ASTM D1505 |

0.940 g/cc |

0.940 g/cc |

0.940 g/cc |

0.940 g/cc |

0.940 g/cc |

|

Tensile Properties |

|

|

|

|

|

|

|

■ Yield strength ■ Break strength ■ Yield elongation ■ Break elongation |

ASTM D6693 Type IV

|

7 kN/m 13 kN/m 12% 700% |

11 kN/m 20 kN/m 12% 700% |

15 kN/m 27 kN/m 12% 700% |

22 kN/m 40 kN/m 12% 700% |

29 kN/m 53 kN/m 12% 700% |

|

■ Tear Resistance |

ASTM D1004 |

62 N |

93 N |

125 N |

187 N |

249 N |

|

■ Puncture Resistance |

ASTM D4833 |

160 N |

240 N |

320 N |

480 N |

640 N |

|

■ Stress Crack Resistance |

ASTM D5397 |

500 hrs |

500 hrs |

500 hrs |

500 hrs |

500 hrs |

|

■ Carbon Black Content |

ASTM D1603 |

2.0% |

2.0% |

2.0% |

2.0% |

2.0% |

|

■ Carbon Black Dispersion |

ASTM D5596 |

For 10 different views:9 in Categories 1 or 2 and 1 in Category 3 |

||||

|

■ Oxidative Induction Time (OIT) |

ASTM D3895 |

100 min. |

100 min. |

100 min. |

100 min. |

100 min. |

|

■ UV Resistance High Pressure OIT retained after 1600hrs |

ASTM D5885 |

50% |

50% |

50% |

50% |

50% |

|

Dimensions |

|

|

|

|

|

|

|

■ Roll Width (m) |

|

7 |

7 |

7 |

7 |

7 |

|

■ Roll Length (m) |

|

420 |

280 |

210 |

140 |

105 |

|

|

Honor

MESSAGE